Facility and Equipment Description

Manufacturing Facility:

48,000 square foot Manufacturing Facility located on 7 Acres Office Complex: 1500 square foot

Manufacturing Equipment:

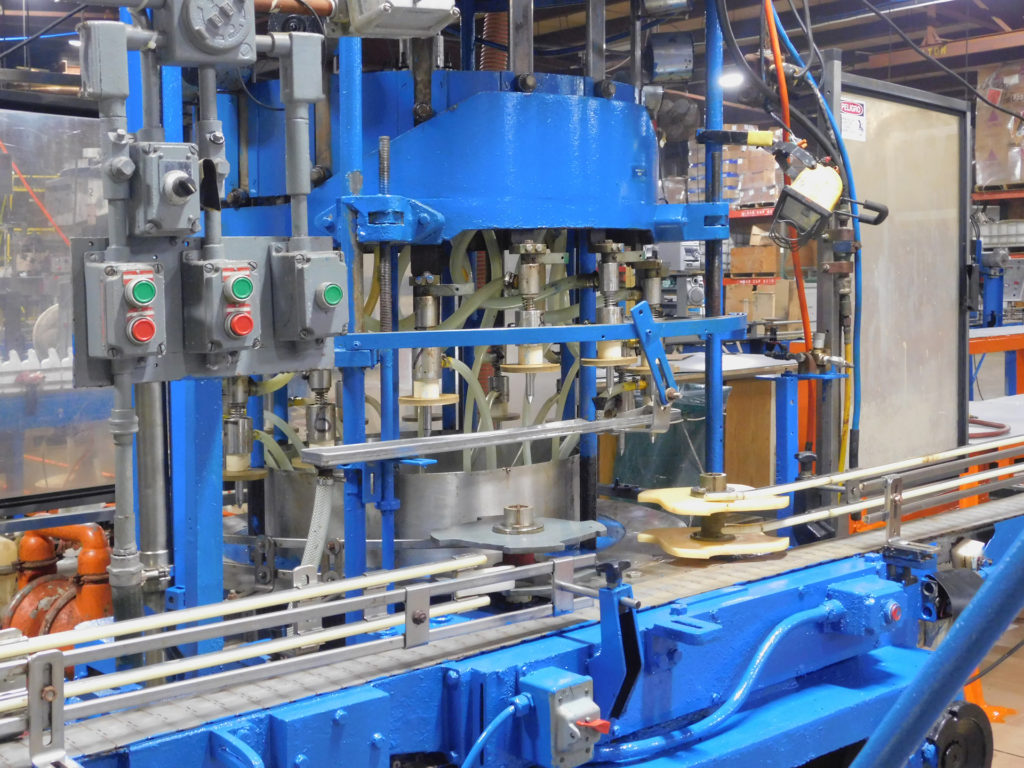

Filling Line #1

30 Head MRM overflow filler with interchangeable nozzles ranging from 1/4” to 1”

Kaps- All Auto Capper-Tightener

Tronics Labeler with Wrap Unit

3M Auto Case Sealer

PrintJet Inline Bottle Coder

Filling Line #2

Automatic Poly Pressure Gravity Filler with 12 – 1/2” and 3/4” Interchangeable TruBlue Actuated Nozzles

Kaps- All Auto Capper-Tightener

Tronics Labeler with Wrap Unit

3M Auto Case Sealer

PrintJet Inline Bottle Coder

Filling Line #3

18 Head MRM overflow filler with interchangeable nozzles ranging from 1/4” to 1”

Kaps- All Auto Capper-Tightener

DPS Specialized Automatic Spout / Plug / Snap Cap Seating Machine

Tronics Labeler with Wrap Unit

3M Auto Case Sealer

PrintJet Inline Bottle Coder

Additional Fillers – DPS Manufactured Portable Plug and Play Specialty Fillers

1 Head Piston Rotary Index Filler for Lotions, High viscosity formulas – With 2oz to 32 oz volume fill Capability

6 Head Portable Gallon Overflow Filler

Portable Pressure Gravity Filler 6 – 12 Head 3/4”True Blue Actuated Nozzles

15 Head rotary filler w Hastoloy Nozzles

Additional Packaging Equipment:

Markem Imaje 5500 Bar Coder Graphic Printer

Portable In-Line Induction sealer

Little David Auto Case Erector – Bottom Case Sealer

3M, Little David Tape Machine

Misc. Conveyors for additional line support

Secondary Packaging Equipment:

2 – Clamco Automatic L- bar Sealers for Over Wrap and Bundling

2 – Clamco Steam Tunnels for Over Wrap, Bundling, Sleeving

1 – Kalfass Automatic L-Bar sealer for Over Wrap, and Bundling accommodates small

packages to large packages up to 3 Ft wide

1 – Kalfass Steam Tunnel – Over Wrap, Bundling, Sleeving accommodates small

packages to large packages up to 3 Ft wide

1 – Shanklin Steam Tunnel for Over Wrap, Bundling, Sleeving

Blending Equipment:

Di Water System

Industrial On- Demand Hot Water System

Blend Tanks

4 – 5000 gallon Fiberglass Blend tanks with mixing props

1 – 3000 gallon Stainless Steel Blend tank with side sweeping mixing blades

2 – 1600 gallon Fiberglass Blend Tanks with mixing props and load cells

1 – 500 gallon Stainless Steel Blend Tank with detachable lightning mixer

Indoor Hold Tanks

4 – 3000 gallon Poly Tanks

3 – 1800 gallon Poly Tanks

2 – 2000 gallon Stainless Steel Tanks

1 – 6500 gallon Fiberglass Tank

1 – 500 gallon Stainless Steel Tank

1 – 300 gallon Poly Tank

1 – 500 gallon Poly Tank

1 – 6500 gallon Fiberglass Tank

Outdoor Hold Tanks

2 – 3000 Gallon Stainless Steel Tanks

3 -10,000 Gallon Stainless Steel Tanks

Pumps

2 – M4 1-1/2” Wilden Diaphragm Poly Pumps

2 – 1-1/2” ARO Diaphragm Poly Pumps

2 – 1”Wilden Diaphragm Pumps

8 – M8 2” Stainless / Aluminum Diaphragm Pumps

3 – M15 3” Stainless / Aluminum Diaphragm Pumps

2 – 3⁄4 hp Waukashaw Pumps

Various small centrifugal pumps

Misc. Equipment

Tri-clover Blender

Various size portable lightning mixers for totes and drums.